Health and Safety

COMMITMENT: ZERO HARM

We are committed to building a zero harm culture that targets continuous improvement and an ever-safer working environment that ensures the health and wellbeing of people.

Providing a safe and healthy working environment is a prerequisite for a modern, responsible business. Our aim is to ensure that everyone goes home without harm at the end of each day and works in an environment where their health is prioritised and safeguarded.

Health and safety is a core Tarmac value – not just for our employees but for contractors and anyone else that comes into contact with our business. This is reflected in our commitment to achieving zero harm.

2020 MILESTONE: ACHIEVE ZERO HARM

Safety

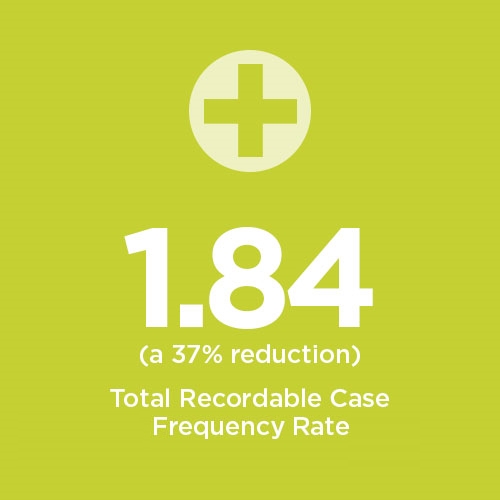

We monitor and report the safety performance of all of our operations and include both employees and contractors in our reporting. Across our business operations in 2016, we reduced our Total Recordable Case Frequency Rate (TRCFR) for employees, contractors and other workers to 1.84 incidents for every million hours worked. This represented a 3% improvement from 2015 and continued our journey towards zero harm. There were 58 recordable incidents across the business in 2016, down from 59 in 2015. Whilst we have improved our performance, we remain committed to further driving continuous improvement to bring down incident rates towards our commitment, achieving zero harm.

Our continued focus on improving health and safety performance was recognised at the Mineral Products Association (MPA) Health & Safety Awards 2016, where our Building Products team won the Blue Circle Transport Award for improving the vehicle and pedestrian movement plan at its Glasgow DSM Mortar plant and received another award of merit for work on an engineered process to automatically measure block heights at Newark Topblock which reduces operator exposure to moving machinery. Our Marine business also picked up a Highly Commended award for our ongoing work around contractor engagement.

Read our case study: Award Winners – MPA Health and Safety Awards 2016 or Watch the film

Total Recordable Case Frequency Rate (TRCFR)

Number of incidents in 2016

Number of incidents in 2015

Number of incidents in 2014

OHSAS 18001

Our OHSAS 18001 management system continued to gain maturity across all our operational sites during 2016 and work will continue in preparation for the transition to the new international occupational health and safety standard ISO 45001, which we expect to implement in early 2018.

Safety week

In June 2016, all Tarmac staff took part in our annual Safety Week. Safety Week is aimed at building on our day to day safety activities by taking extra time out to engage in a range of health and safety related activities on themes such as traffic management, hazard awareness, road haulage, and health and wellbeing.

Employee Engagement

Worker engagement and collaborative working are essential foundations for us to realise our commitment to achieving zero harm. In 2016, work commenced on the development of a new safety leadership interaction programme, focused on improving employee engagement at all levels across the Tarmac business. The revised programme was designed to align with the our parent company CRH’s safety leadership interaction programme and aims to actively engage employees on health and safety matters.

Health and Safety Leadership

Tarmac has reviewed it’s model for health and safety leadership in 2016, by focusing the drive towards zero harm through a health and safety leadership team lead and driven by senior individuals from within business units in Tarmac. The specific aim is to set and coordinate efforts our strategic approach and to drive ownership from within business around the health and safety challenges that it faces.

Life Saving Rules

During 2016, Tarmac continued to embed the CRH Life Saving Rules across all operations and review health and safety standards to fully reflect key operating requirements. Tarmac has also aligned the site risk register process to reflect the Life Saving Rule requirements. Life Saving Rules is a safety awareness campaign, supported by a series of line manager briefings, videos and interactive toolbox talks that focus on the 16 causes of all fatal and serious injuries that have happened across CRH group.

Health

Throughout 2016 we continued to roll out our health management programme. We launched a new Drugs and Alcohol Policy setting out our rules on drug, alcohol and substance misuse, how we test for them, and what to do if someone has a problem with drugs and alcohol addiction or abuse. The launch was supported by employee briefings and an awareness campaign reminding employees about the dangers of drug or alcohol abuse and the help available offered by Tarmac should people need it.

A role specific health matrix was also established, which requires, a pre-employment medical check and an appropriate type and frequency of health surveillance dependant on job role for employees.

A standardised ’Fit for Work’ medical has been implemented, that will be delivered every two years until the age of 60 and then annually thereafter This will help tarmac to ensure compliance with HSE safety critical guidelines for all operational employees.

The ‘Fit for Work’ process also provides a ‘Fit for Work’ certificate for each operative and includes all elements of health surveillance, such as; audiometry (hearing), spirometry (lung function), skin, hand arm vibration and vision. Wellbeing elements, including blood pressure and urinalysis are also included.

In 2016 we had carried out health surveillance on 3,365 employees (approximately 70% of our operational population), with the remainder planned for completion by the end of Q2 2017.

In support of our health assessments, we are developing a health intervention process, which will ensure visibility, understanding and the retention of the outcomes of health surveillance, working closely with front line managers, the safety team and our operational staff. An improved system of monthly KPI’s is now available to track and monitor health of employees and allow us to better identify opportunities to support employees in improving health. This is an essential step to ensure the health and wellbeing of our workforce and control of risk to health at point of contact.

Looking ahead

In 2017 we will be introducing a revised peer review process for all of our operational sites with the aim of delivering improved performance at an operational level with employees and contractors alike. This peer review process will also support our safety assurance processes. Tarmac will also be working towards integrating its key management systems and the transition to the new ISO 45001 standard.