Climate Change

COMMITMENT: DESIGN CO2 OUT OF OUR PRODUCTS AND SERVICES

Climate change affects us all, and will have significant impacts on society and the environment unless everyone takes action to limit its effects. As the construction, maintenance and use of buildings and infrastructure accounts for more than half of the UK’s greenhouse gas emissions, we recognize the role the construction sector and Tarmac have to play in taking action to reduce our emissions and supporting others to do the same.

We are making progress right across our business and supply chain, using a whole life-cycle approach to design CO2 out of our products and services. This includes working with suppliers to reduce CO2 from the goods and services we buy, cutting CO2 from our operations and transport, innovating lower CO2 products, services and solutions that reduce CO2 from the construction process or during the use of infrastructure and buildings. We are also working to reduce CO2 by recycling materials at the end of their current life. Climate change presents us with challenges, but our ability to innovate in this area is also opening up new business opportunities and new ways to support the delivery of a low carbon built environment.

2020 MILESTONE: Achieve 37% reduction in CO2 per tonne of product compared to 1990 (i.e. 15% compared to 2013)

Reducing our footprint

By the end of 2016 we had achieved a 23.5% reduction in CO2 per tonne of product compared to 1990, which means we are making progress towards our 2020 target.

We categorise our greenhouse gas emissions into direct and indirect sources in line with the Greenhouse Gas Protocol.

WHAT WE MEAN BY CO2e

Carbon dioxide is one of six greenhouse gases that are emitted when humans undertake certain activities. Other greenhouse gases include methane, nitrous oxide and ozone – all of which occur naturally in our atmosphere. To take into account the emission of other greenhouse gases when calculating the level of greenhouse gas emissions, scientists have devised an equivalent measure – CO2e (which literally means carbon dioxide equivalent). CO2e allows other greenhouse gas emissions to be expressed in terms of CO2 based on their relative global warming potential (GWP).

So when you see a carbon footprint expressed in terms of CO2e, you can know for sure that all greenhouse gases have been included for each activity under scope, and therefore a fuller picture of an organisations impact has been captured.

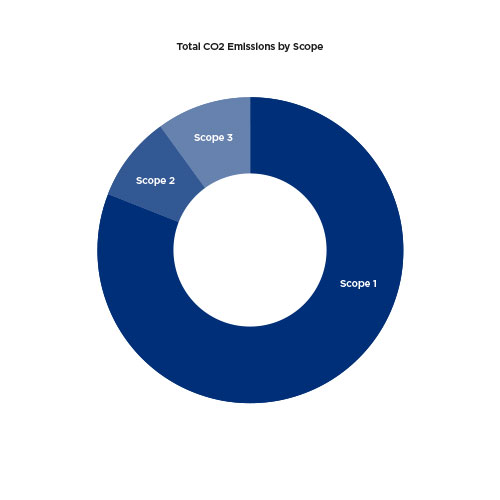

Tarmac CO2 emissions by Scope

| 1000’s tCO2e | % | |

| Scope 1 | 2,282.20 | 81% |

| Scope 2 | 244.25 | 8.7% |

| Scope 3 | 281.76 | 10.3% |

| 2,808.21 | 100% |

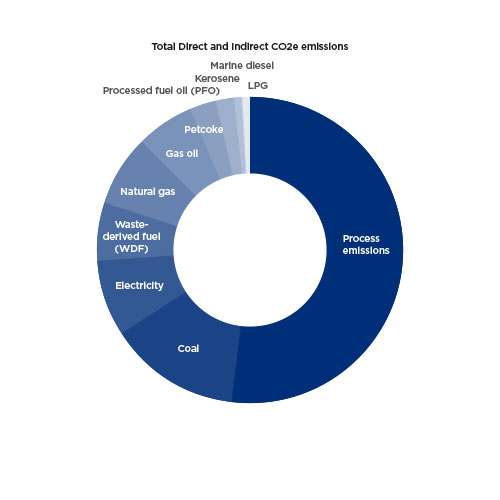

While our total CO2e has reduced significantly since 1990 due to investment in energy and CO2e efficiency measures. Our emissions over recent years show only a slight improvement and this is due in part to market increase and output. The largest proportion of our Scope 1 emissions are ‘process emissions’ from the chemical reactions that take place when we manufacture cement and lime. This accounts for over half of all our emissions. The remainder of our Scope 1 emissions come from the combustion of fuels used to power the process.

Direct and indirect CO2e emissions for Tarmac

| tCO2e | % | |

| Process emissions | 1,288,668 | 52.2% |

| Coal | 343,885 | 13.9% |

| Electricity | 196,992 | 8.0% |

| Waste-derived fuel (WDF) (from fossil sources) | 148,403 | 6.0% |

| Natural gas | 187,155 | 7.6% |

| Gas oil | 146,981 | 6.0% |

| Petcoke | 72,700 | 2.9% |

| Processed fuel oil (PFO) | 45,948 | 1.9% |

| Kerosene | 18,087 | 0.7% |

| Marine diesel | 2,014 | 0.1% |

| LPG | 16,369 | 0.7% |

| Total | 2,467,202 | 100% |

Our reduction in CO2 per tonne of production has been achieved in 2016 by:

Investing in new plant and equipment

Investment in more efficient plant and equipment helps us to cut energy use and reduce CO2. For example,in 2016 Tarmac invested over a million pounds across its aggregates and asphalt business unit in projects to reduce energy and fuel use. On our asphalt plants we have invested significant resource into increasing our recycled asphalt planings (RAP) capabilities. Other investments have included converting asphalt plants to LPG, installing low temperature asphalt systems at our Hothfield plant, enabling bitumen blending at our Stancombe and Banbury sites and installing telemetry on all of our mobile plant.

Read our case study: New plant and equipment / RAP / Telogis

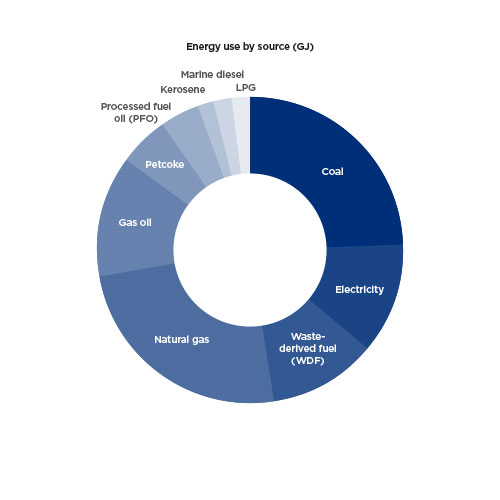

Energy use by source (GJ)

| Energy use by source (GJ) | % | |

| Coal | 3,654,000 | 24.56% |

| Electricity | 1,721,084 | 11.57% |

| Waste-derived fuel (WDF) | 1,703,000 | 11.44% |

| Natural gas | 3,673,892 | 24.69% |

| Gas oil | 1,915,627 | 12.87% |

| Petcoke | 783,000 | 5.26% |

| Processed fuel oil (PFO) | 617,291 | 4.15% |

| Kerosene | 264,559 | 1.78% |

| Marine diesel | 273,576 | 1.84% |

| LPG | 274,826 | 0.98% |

| Total | 14,880,855 | 100% |

Energy efficiency programmes

In 2016 we have further embedded the ISO 50001 energy management system across our entire business, supported by our internal and external audit programme. We also use the ISO 50001 system to ensure all our operations are compliant with regulatory requirements, such as the UK government’s new Energy Savings Opportunity Scheme (ESOS), and to drive continuous improvement in energy and CO2 efficiency. We set every site a specific energy and CO2 target and require each to generate an energy reduction opportunities assessment. This process is supported the sharing of best practice energy efficiency measures across relevant operations. Progress is regularly reviewed and energy management training programmes have been implemented.

In 2016 our company wide ‘Re-energise’ campaign, which helps employees to identify ways to save energy, continued with the ‘Re-energise Calendar’. The Calendar provides employees with monthly energy efficiency ideas and opportunities to consider and address at their site. Using the Calendar employees are given support in areas such as improving pumping efficiency, fuel management systems and reducing electricity base load.

In Aggregates and Asphalt we continued to build upon 2015’s success with our Optimise programme, taking control and ownership of a process that was initially supported by consultants as detailed in the case study below.

Dynamic demand

In 2016 we completed the implementation of our Dynamic Demand technology partnership with the UK’s leading Demand Side Response (DSR) Company, Open Energi. We installed the technology on more than 200 bitumen tanks at over 70 of our asphalt plants. When there is a high electricity demand on the national grid, the Dynamic Demand system automatically adjusts power consumption on our bitumen tanks to help manage the spike in demand, while ensuring that bitumen tanks are kept at the required temperature for production. Not wanting to stop there, we continue to investigate other installations that could be used to help balance the grid.

Read our case study: Helping to manage national energy demand

Using lower CO2 fuels

In our cement business we are increasing the use of waste-derived fuels and biomass fuels as a way of reducing CO2 emissions. By using waste-derived fuels we not only reduce our CO2 emissions; we conserve valuable natural resources and help to reduce the amount of waste that goes to landfill. In 2016, 28.5% of the heat input to our cement kilns was produced from waste-derived fuels, including 12.7% from biomass. Our performance is down slightly on previous years due to technical / production issues at one of our cement plants. The types of fuels used in 2016 included waste tyres (whole or chipped), solid recovered fuel (SRF) from non-hazardous materials including paper, cardboard, plastics, textiles and wood chips, meat and bone meal (MBM), recycled liquid fuel, processed sewage pellets (PSP) and polymer chip. Fuels such as MBM and PSP are 100% biomass and tyres, SRF and polymer chip contain a proportion of biomass. The use of fuels containing biomass makes a significant contribution to reducing CO2 emissions because biomass is considered carbon neutral.

Within our aggregates and asphalt business we are converting many of our operations to use lower CO2 fuels, for instance from oil to natural gas or LPG. In 2016 we converted our Caldon, Trowse, Dolyhir and Stancombe plants from running on a processed fuel oil to running on LPG.

Read our case studies:

– Alternative fuels for a more sustainable business

– Using waste-derived fuels

Transport efficiency and telematics

In 2016 we remained committed to move more of our product delivery from road to rail. We invested into re-opening and improving our rail facility at Aberthaw cement works, South Wales and Arcow Quarry in the Yorkshire Dales to reduce road transport and achieved over 9 million tonnes by rail in 2016, that’s equivalent to removing 450,000 lorries load from our roads.

Read our case study: Transport

A considerable amount of our materials are purchased locally to their manufacture and road transport is often still the most appropriate mode of transport. We continue to work hard to improve the way we use our vehicles. This has included maximising payloads to minimise the number of trips required. We also try to ensure where possible that we supply from the nearest available unit and plan delivery routes to avoid congestion. We regularly upgrade our fleet and are encouraging our contract hauliers to move to the latest generation of Euro VI engines. We have also invested in high tech fuel monitoring equipment on our marine dredging vessels to ensure we have the best possible understanding of our fuel use on board.

Working with suppliers

Encouraging suppliers to introduce energy efficiency measures which help to lower the carbon footprint of our business is an important element of our approach to responsible procurement. For example, our work with Flogas to develop a custom built LPG plant to deliver a seamless transition to a smarter, cleaner burning fuel, the first of its kind in the UK. These new plants use a liquid LPG pumped system, incorporating fuel burners, to provide a total solution.

Read our case study: Developing state of the art technology to drive down carbon emissions

Product innovation

We support customers and end users to create more energy efficient, lower carbon buildings and infrastructure by considering the whole-life (capital and operational) carbon associated with our products by redesigning and rethinking the way we make them. Among options we consider are:

- improving durability, meaning that products need to be replaced or maintained less frequently

- using recycled or secondary materials in products, such as ground granulated blast furnace slag and fly ash instead of clinker to reduce the capital CO2 in cement or used road surfacing (Recycled Asphalt Planings) instead of primary materials in asphalt

- creating new products that will produce lower carbon emissions – such as our lower temperature asphalts, which can be manufactured at lower temperatures and therefore save on energy and CO2

- providing customers with product carbon footprint information generated from our calculator tool that measures carbon across a project enabling better choices about design and what materials to use

- raising awareness of the benefits of our materials in use through Solution Guides

Tarmac is a key signatory of the UK Government’s Infrastructure Carbon Review (ICR) which aims to cut 24 million tonnes CO2 from UK infrastructure projects by 2050. In support of the ICR we have played an active role in the development of a new publicly available standard PAS 2080, the world’s first specification for Carbon Management in Infrastructure which was released in May 2016. Read it here.

Read our case study: Tarmac’s Solution Guides help customers deliver a sustainable built environment